5-layer co-extrusion technology is separate conflicting chemical additives into independent layers, resulting in 30% to 50% higher mechanical strength, permanent anti-drip performance, and light transmission up to 95%.

5-layer co-extrusion technology is the only way to separate conflicting chemical additives into independent layers, resulting in 30% to 50% higher mechanical strength, permanent anti-drip performance, and light transmission up to 95%.

By moving away from monolayer or 3-layer films, At HONREL AGRICULTURE, we’ve seen growers switch to 5-layer Greenhouse Film and cut their labor costs in half because the film lasts 5 to 7 years instead of two. In this guide, we will break down the technical ROI, the science of the “sandwich” structure, and why this is the only logical choice for distributors and commercial farms in 2026.

Let’s be honest: in a 3-layer film, you are forcing UV stabilizers, anti-drip surfactants, and thermal IR-blockers to live in the same space. These chemicals often “fight” each other. This is known in the industry as additive interference. When they fight, they “bloom” (create a white powdery residue) or leach out too fast, meaning your anti-drip fails in six months.

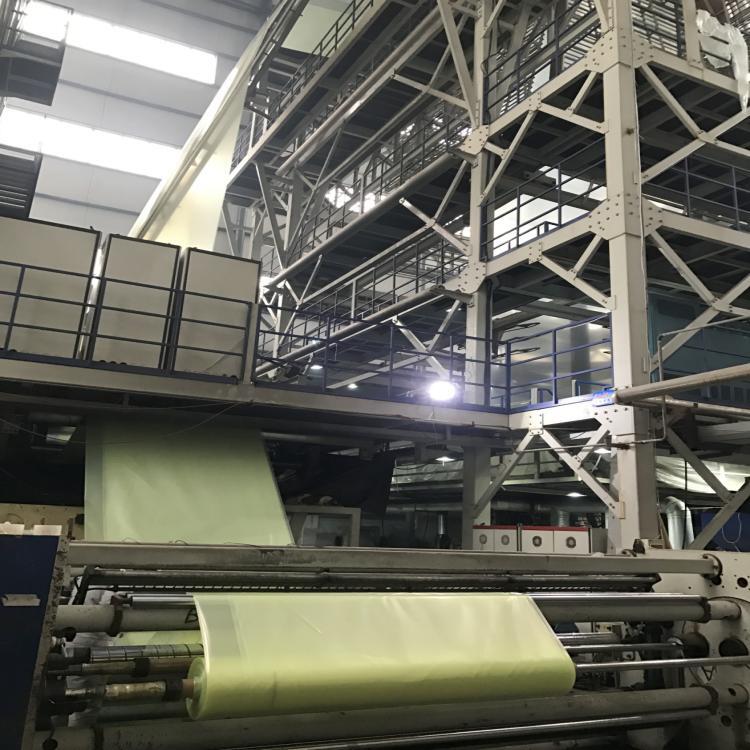

With our 5-layer co-extrusion process, we isolate these additives. We put the “anti-dust” properties on the outside, the “strength” in the core, and the “anti-drip” on the inside. This ensures that every layer does exactly what it was engineered to do for the entire life of the film.

According to research from the International Society for Horticultural Science (ISHS), multi-layer films that optimize spectral transmission can boost vegetable yields by as much as 20% compared to standard PE films.

In a 5-layer stack, we can use 100% pure Metallocene LLDPE in the core layers. This resin acts as the “skeleton” of the film. It provides incredible dart impact resistance and tensile strength. For a wholesaler, this means fewer complaints about tearing during high-wind events or mechanical installation.

As a leading Agricultural PE Film Manufacturer, we don’t just blow plastic; we engineer it. Here is how a typical 5-layer performance film is structured:

The KLY (Kilolangley) RatingNever buy a “standard” film for a global market. A film designed for 100 KLY (like Northern Europe) will disintegrate in 18 months in a 180 KLY zone like Arizona or Spain. We always recommend that distributors specify the destination region so we can tune the UV stabilizers in Layer 2 to match the local solar radiation levels.

If you are presenting a quote to a commercial farm, you need to show the data. Here is the technical reality:

| Technical Feature | Traditional 3-Layer Film | Advanced 5-Layer Film | Impact on Your Yield |

| Tensile Strength | 18 – 22 MPa | 25 – 35+ MPa | Survives high winds/snow |

| Light Transmission | 88% – 90% | 92% – 95% | Faster photosynthesis |

| Anti-Drip Lifespan | 6 – 12 Months | 3 – 5+ Years | Drastically lower rot/mold |

| Gauge Uniformity | +/- 10% | +/- 3% | No “thin spots” that tear |

| Service Life | 2 – 3 Years | 5 – 7 Years | 50% lower labor cost |

Data synthesized from HONREL Internal Labs and Infunplastic 2026 Technical Datasheets.

For growers who require peak precision, we suggest moving toward PO Greenhouse Film. The 5-layer PO structure is specifically designed for high-value crops like berries and medicinal cannabis where light quality is non-negotiable.

We often talk to B2B buyers who are worried about the initial CAPEX. But let’s look at the “Total Cost of Ownership.”

Replacing a greenhouse cover is a labor-intensive nightmare. If you buy a cheap film that fails in two years, you have to pay a crew to re-skin the entire range. If you buy a 5-layer film that lasts six years, you have saved two entire cycles of labor and downtime.

Furthermore, 5-layer films are not just for roofs. We apply the same technology to our Mulch Film production. By using multi-layer co-extrusion in mulch, we can create a film that is thinner (saving you money on weight) but stronger (so it doesn’t tear when the tractor lays it). If you are looking for a Wholesale Mulch Film Manufacturer, always ask about their layer count.

Best Practice: The Tensioning SecretWhen installing 5-layer film, tension it on a calm morning between 15°C and 25°C. Because these films contain Metallocene, they have a “memory.” If you overstretch them in the heat, they won’t contract properly when it cools down. this prevents “fluttering,” which is the cause of mechanical wear against the frame.

The performance of 5-layer technology isn’t limited to light transmission. For our dairy and livestock clients, we utilize this same machinery to produce Silage Film.

In silage, the goal is an oxygen-free environment. A 5-layer co-extrusion silage wrap provides a superior oxygen barrier compared to 3-layer versions. This ensures that the fermentation process is perfect, preventing spoilage and keeping the nutritional value of the fodder at its peak.

Research from Penn State Extension shows that high-quality oxygen-barrier films can reduce dry matter loss by up to 5%, which translates to thousands of dollars in saved feed for large herds.

At HONREL AGRICULTURE, we understand that a distributor in Australia has different needs than one in Canada. This is where our OEM capability shines.

A: Actually, it’s the opposite. Because we use Metallocene, the film is more flexible and “elastic.” It’s much easier to pull over a large structure without it snapping or creaking.

A: There are two common reasons. First, check your roof slope; it needs to be at least 15–20 degrees. Second, check if you installed it upside down! The nano-coating is only on the inner layer (Layer 5). We mark the “inside” of every roll clearly.

A: You can, but it might be overkill. For seasonal low tunnels, a high-quality Mulch Film or a standard PE film is usually enough. 5-layer technology is best utilized for permanent structures where longevity is the goal.

A: Only if it’s a UV-block film. If you use bees for pollination, we can manufacture a “UV-Open” 5-layer film that allows the specific spectrum bees need for navigation, while still protecting the plastic from aging.

A: We typically run a 3–4 week production cycle for custom OEM orders. For standard 150-200 micron films, we often have stock ready for immediate shipment.

The agricultural world is moving faster than ever. To remain competitive as a distributor or a commercial farmer, you need materials that work as hard as you do.

By choosing HONREL AGRICULTURE‘s 5-layer co-extrusion products, you are getting:

Whether you are looking for the best PO Greenhouse Film for a new cannabis project or a massive bulk supply of Silage Film for a dairy cooperative, our 5-layer technology is the answer.

Selecting the right Greenhouse Film or shade mesh is critical for crop success. As a dedicated Agricultural Netting and Film Manufacturer, our experts help you customize UV protection and light transmission based on your local climate. Share your project details for a tailored solution.