At HONREL AGRICULTURE, we have seen the shift in the global blueberry market. As heat waves become more frequent, "naked" orchards are losing money.

The right shade net is not just a sun-blocker; it is a yield-optimization engine. By choosing a custom-fabricated shade net, you can increase your marketable fruit by up to 25%, reduce water consumption by 20%, and virtually eliminate sunscald and leaf scorch on tender nursery seedlings.

At HONREL AGRICULTURE, we have seen the shift in the global blueberry market. As heat waves become more frequent, “naked” orchards are losing money. Professional growers are moving toward high-density polyethylene (HDPE) Shade Net solutions to control the microclimate from the lab stage all the way to harvest.

Blueberries (Vaccinium corymbosum) are sensitive souls. They love light for photosynthesis, but they hate the heat that often comes with it. When leaf temperatures exceed 30°C, the plant’s stomata close to save water, essentially shutting down growth.

In our experience, the most critical phase is the nursery. Tender shoots don’t have the waxy cuticle of a mature bush. Without shading, these seedlings experience “transplant shock” and high mortality.

According to data synthesized from University of Georgia and Oregon State University, shaded plants maintain a 10% higher relative humidity, which significantly reduces physiological stress and leaf scorch (Source: Oregon State University/Top Greenhouse Tech).

It isn’t just about survival; it’s about profit. A landmark study in Chile found that using specific gray and white nets increased yields by 60% to 91% in the first year because it optimized the light spectrum for fruit set (Source: Retamales et al., 2008).

One of the biggest mistakes we see in wholesale sourcing is “over-shading.” If you block too much light, your sugar content (°Brix) will drop, and your fruit will be bland.

| Variety / Stage | Ideal Shade % | Primary Benefit | Regional Use Case |

| Nursery Seedlings | 50% – 70% | Prevents tender shoot burn | High-intensity (FL, QLD) |

| Northern Highbush | 30% – 40% | Balanced photosynthesis | Temperate (MI, OR, Chile) |

| Southern Highbush | 40% – 50% | Mitigates severe heat stress | Subtropical (GA, Spain) |

| Rabbiteye | 20% – 30% | Protects fruit from sunscald | Hardy variety (TX, NC) |

If you are moving blueberries from tissue culture to the nursery, start them under a 70% custom net. Over a 4-week period, transition them to a 30% or 40% net. This “hardens” the cell walls of the leaves, preparing them for the intense UV of the open field without the high mortality rates common in unshaded nurseries.

For nurseries that use structure-based protection, we often recommend combining these nets with high-quality Greenhouse film to manage both light and rain during the sensitive early-growth phases.

We often get asked: “Does color really matter?” The answer is a resounding yes. The color of your agricultural netting acts as a filter that tells the plant how to grow.

As a shade net wholesale supplier, we don’t just provide the rolls; we provide the solution for the structure.

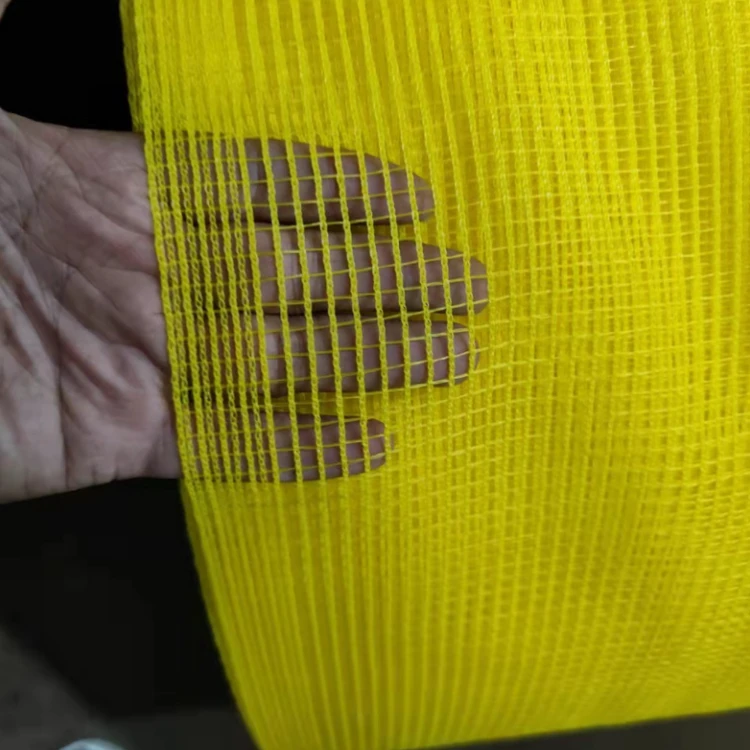

For nursery benches, we provide custom-width shade net manufacturer rolls with reinforced edges and brass grommets. This allows you to snap them onto hoop frames quickly.

For mature orchards, we see a trend toward “permanent canopies.” These structures stay up for 5–8 years. Because our HDPE is UV-stabilized with HALS (Hindered Amine Light Stabilizers), it can withstand intense solar radiation without becoming brittle.

Best Practice #2: The Dual-Protection Hack

Many of our clients use our shade nets as a dual-purpose tool. By selecting a mesh size in the 15-20mm range, the net acts as a shade source AND an exclusion tool. If you are worried about starlings or silvereyes, check out our Anti-bird netting manufacturer specs to ensure you are getting bird protection alongside your UV control.

In the B2B world, the “cheapest” net is often the most expensive because it fails after 18 months. When you are evaluating a Shade Net Manufacturer, ask these three questions:

At HONREL AGRICULTURE, we also suggest growers look at their soil management. While our nets protect the top, using mulch film at the bottom ensures soil moisture is retained, creating a total protection system for your crop.

A: Only if you over-shade. Studies show that a 30%–35% white or gray net actually maintains or slightly increases sugar content because the plant isn’t under heat stress. However, 70% shade is only for nurseries; using it on mature fruit will result in lower sugar levels.

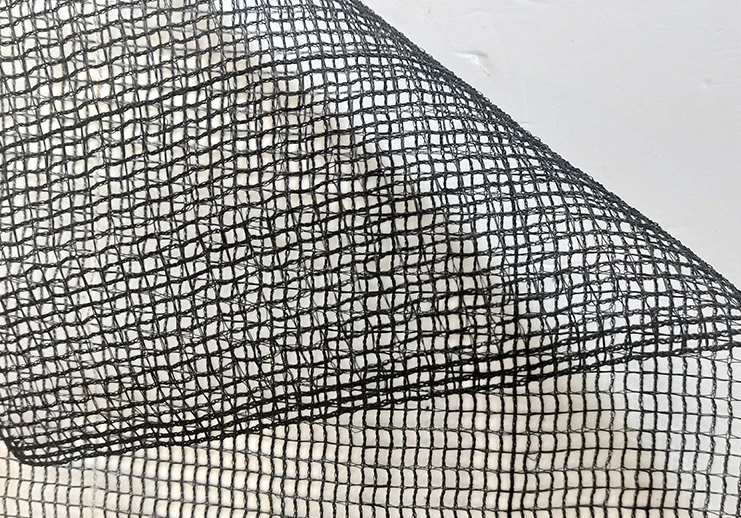

A: We don’t recommend it. Black cloth absorbs solar energy and can actually “radiate” heat down onto the plants. For hot regions (Zones 8-10), white or reflective Aluminet is far superior.

A: By reducing the canopy temperature and wind speed, evapotranspiration is cut by nearly 20% (Source: Oregon State University). This means your drip irrigation system doesn’t have to work nearly as hard.

A: For wholesale container loads, our lead time is typically 3–4 weeks. We offer custom widths to match your specific row spacing, reducing waste during installation.

A: Yes, our knitted HDPE shade nets are designed with a “rip-stop” pattern. While not a dedicated hail net, they provide significant protection against small-to-medium hail stones, preventing fruit bruising.

We believe that the future of blueberry farming is in precision climate control. At HONREL AGRICULTURE, our mission is to provide distributors and large-scale nurseries with the highest-quality shading solutions that are built to last. We don’t just sell nets; we sell the peace of mind that your harvest is protected from the elements.

Whether you are building a new nursery or upgrading a 100-hectare orchard, our team is here to provide the technical specs and factory-direct pricing you need to succeed.

Selecting the right Greenhouse Film or shade mesh is critical for crop success. As a dedicated Agricultural Netting and Film Manufacturer, our experts help you customize UV protection and light transmission based on your local climate. Share your project details for a tailored solution.