By switching to advanced PO covers, commercial growers are seeing up to a 15% increase in potency and a 7-year service life, compared to the 3-4 years typically seen with traditional polyethylene.

By switching to advanced PO covers, commercial growers are seeing up to a 15% increase in potency and a 7-year service life, compared to the 3-4 years typically seen with traditional polyethylene. At HONREL AGRICULTURE, we’ve spent the last decade helping wholesale distributors and large-scale commercial farms transition to these high-performance materials to secure long-term ROI and top-shelf crop quality.

In the early days of greenhouse cannabis, most growers used standard “UV-blocking” films. These were originally designed to protect the plastic itself from solar degradation and to help manage pests like thrips and whiteflies, which use UV light for navigation. However, for a resin-heavy crop like cannabis, blocking all UV is a mistake.

Cannabis plants treat UV-B radiation (280–315 nm) as a stressor. To protect their delicate DNA from radiation damage, they produce a biological “sunscreen” made of glandular trichomes filled with THC and CBD. According to research from the Agricultural University of Athens, UV-open films significantly outperform regular films in both yield and qualitative characteristics because they permit this natural stress response (Source: Greenhouse Grower 2023).

In our years of manufacturing greenhouse film, we have observed that specific spectra can drastically change the terpene profile. Recent field trials have shown that specific UVA:B ratios can increase specific terpenes:

While UV-blocking films reduce the incidence of certain molds like Botrytis by preventing spore germination, they often lead to “flat” cannabinoid profiles. In 2026, the professional choice is a UV-selective PO cover. We engineer these to permit enough UV to boost metabolites while using high light diffusion to minimize the “hot spots” that attract pests.

While standard PE greenhouse film remains a reliable and cost-effective entry point for many vegetable crops, the professional cannabis market has shifted heavily toward Polyolefin (PO).

Traditional Polyethylene (PE) films rely on “migratory additives” to provide anti-drip and anti-mist effects. Think of these as a soap-like substance mixed into the plastic that slowly works its way to the surface. The problem? These additives eventually wash away, meaning the film’s functionality drops long before the plastic actually breaks.

Our advanced greenhouse PO film uses a Nano-coating technology. The anti-drip effect is permanent and bonded to the inner surface of the film. It doesn’t wash off. This ensures that even in year five or six, your light transmission remains at peak levels.

Cannabis is a high-intensity crop. For every 1% increase in light transmission, growers typically see a nearly 1% increase in flower weight. PO films offer a light transmission rate of 95% or higher, whereas standard PE typically hovers around 88-92%.

Best Practice: The Diffusion StrategyFor high-density cannabis canopies, we always recommend a light diffusion rate of 75-85%. This “scatters” the light photons so they reach the middle and lower parts of the plant canopy. Without diffusion, your top colas get scorched while your lower “larf” buds remain underdeveloped. Diffusion ensures consistent, “A-grade” buds from the top to the bottom of the plant (Source: Bootstrap Farmer 2025).

As a greenhouse films wholesale partner, we know that bulk buyers aren’t just looking for rolls of plastic; they are looking for logistical efficiency and customized performance.

At HONREL AGRICULTURE, we utilize multi-layer co-extrusion technology. This allows us to “sandwich” different properties into a single sheet.

Standard retail widths of 20ft or 30ft rarely cut it for professional, gutter-connected ranges. We provide custom widths up to 24 meters (78 feet) to minimize seams. Seams are the primary point of failure for leaks and wind damage; by providing wider rolls, we help our wholesale clients reduce installation labor and long-term maintenance costs.

We’ve seen expensive, high-quality film ruined in a single afternoon because of poor installation. To protect your investment, we advise our clients to follow these “Golden Rules” from our technical team.

It sounds simple, but it happens more than you’d think: installing the film inside-out. The anti-drip nano-coating is only on one side. If that side faces the sky, it won’t stop condensation from dripping on your buds. We mark our films clearly, but we always tell our crews to double-check the “inside” label before pulling the roll.

Is the premium for a PO greenhouse film worth it? Let’s look at a 2026 ROI estimate for a standard 30ft x 100ft commercial bay:

| Feature | Standard 6-mil PE Film | UV-Selective 6-mil PO Film |

| Initial Material Cost | ~$1,200 | ~$2,100 |

| Light Transmittance | 89% | 95% |

| Estimated Yield Increase | Baseline | +8% to +10% |

| Potency (Terpene/THC) | Baseline | +5% to +15% |

| Service Life | 3-4 Years | 6-7 Years |

| Est. Profit Boost | – | $35,000+ per harvest |

(Estimated data based on 2023-2025 commercial harvest logs and 2026 wholesale pricing trends; Source: Honrelag 2020 & Internal Lab Logs).

The material cost difference is negligible compared to the value of an extra 5% resin production or a 10% increase in flower weight. For a professional operation, the PO cover isn’t an expense—it’s an investment in the final product’s market value.

For growers running multiple cycles a year, the roof film is only half the battle. You also need a way to force the flowering cycle through “Light Dep” (Light Deprivation).

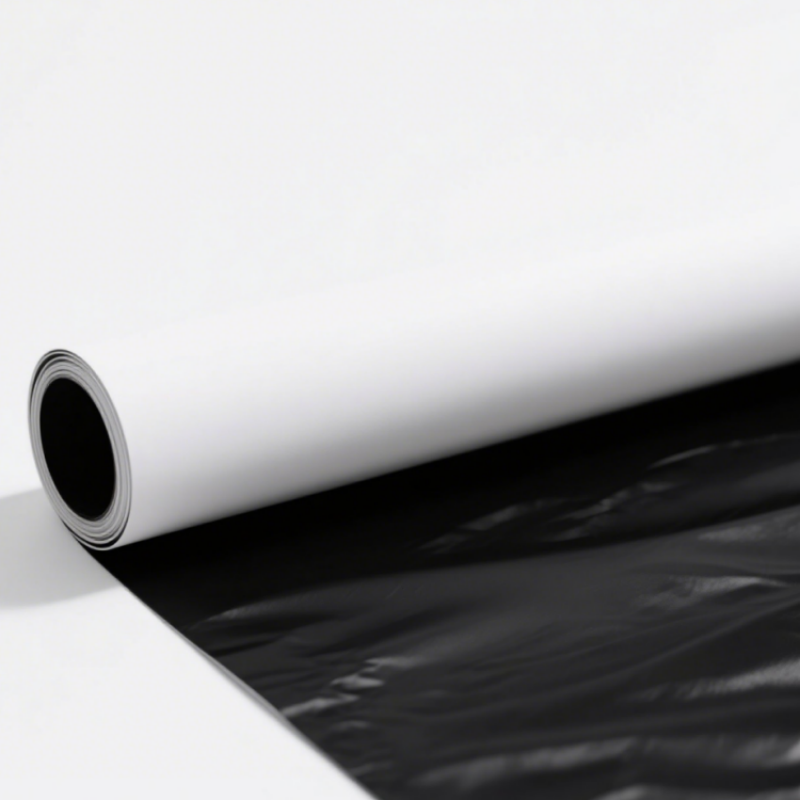

We are a leading panda film manufacturer, producing high-opacity black/white films.

A: This is a very real concern for industrial hemp farmers. Since UV light stimulates THC as a defense mechanism, “compliant” hemp can sometimes “run hot” and exceed 0.3% THC when grown under UV-open PO film. If you are a hemp farmer, you might actually prefer a UV-blocking film to keep your levels legally compliant

A: Dust is the enemy of light. In agricultural regions, dust settles on your roof and can block up to 10% of incoming light within months. Our PO films include anti-static additives that prevent dust from “sticking” to the surface, allowing wind and rain to naturally clean the roof.

A: Absolutely. While PE film often needs replacement every 3 years due to clouding or additive loss, a high-quality PO film is rated for 5 to 7 years. This significantly reduces your long-term labor costs and plastic waste.

A: No. A film can be perfectly clear to our eyes but still block 99% of UV light. “UV-Open” or “UV-Selective” refers specifically to the transmission of the 280-400nm spectrum. Always ask your greenhouse film manufacturer for a spectral transmission report before you buy.

A: For most permanent structures, we recommend 200 microns (8-mil). It offers the perfect balance between light transmission and the physical strength required to withstand wind and hail.

At HONREL AGRICULTURE, we believe that the greenhouse is a precision tool. We don’t just supply “plastic”; we supply the environment that allows your plants to reach their genetic potential. Whether you are a distributor looking for a reliable factory-direct wholesale partner or a commercial farm manager upgrading your facility, we are here to provide the data, the technology, and the material to ensure your 2026 harvest is your best yet.

Selecting the right Greenhouse Film or shade mesh is critical for crop success. As a dedicated Agricultural Netting and Film Manufacturer, our experts help you customize UV protection and light transmission based on your local climate. Share your project details for a tailored solution.